Excitement About 24??media

Excitement About 24??media

Blog Article

Not known Facts About 24??media

Table of ContentsThe Main Principles Of 24??media Unknown Facts About 24??mediaThe Of 24??media24??media - An OverviewSee This Report about 24??media

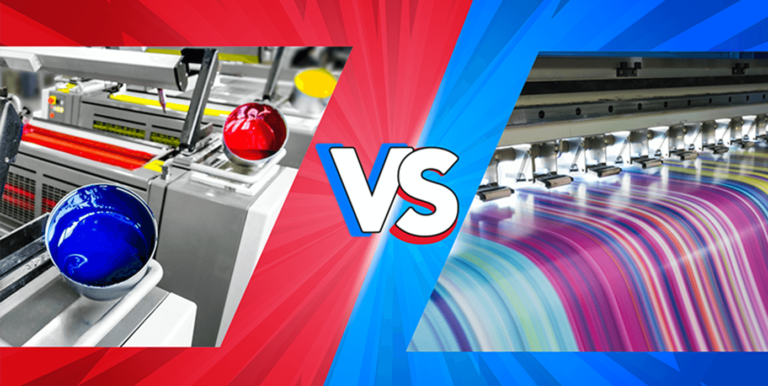

Developments in print innovation are altering the communications playing field when it concerns high quality, affordability and cutting-edge capabilities. Countered printing and electronic printing are the significant processes by which print tasks are carried out both making use of four-color printing techniques. Each choice has its benefits, offering various techniques to satisfy the demands of varied manufacturing tasks.

Typically, this has actually been one of the most consistent method for specifically keeping color matches, making it perfect for print runs that only need static printing such as pre-printed kinds, brochures, leaflets, calling card, and mass postcard mailings. Due to the static nature of litho printing, it is not optimal for variable print pieces that will be sent by mail to individual receivers such as declarations, letters, and customized postcards.

What Does 24??media Do?

The current developments in print innovation are helping to bring most of balanced out's advantages into the digital printing world absolutely transforming the face of modern-day printing! There are some essential differences between Offset Printing and Digital Printing (Stickers). This guide shows the advantages and disadvantages of each printing technique. There is an obvious and growing number of benefits to utilizing the digital print procedure.

Today's digital print devices is among the most advanced on the market. Right here are a few of the most significant benefits of making use of digital printing: dominate the digital print space, with full-color printing completed in one procedure and seamlessly published directly from a print data. Without a prolonged set-up procedure, the calibration time of a particular work is reduced, adding to quicker print time and total shipment.

The inkjet printing procedure has actually aided to transform the market in addition to the high quality and speed of the outcome. The most recent inkjet innovation can print on traditional countered stocks with dull, silk, and shiny finishes. High-quality electronic print combined with software-managed color monitoring practices includes maximum worth to print pieces and makes manufacturing processes extra dependable than offset.

See This Report about 24??media

(https://www.callupcontact.com/b/businessprofile/24Media/9522161)

Eco-friendly and biodegradable inks and printer toners are likewise offered for even more lasting printing. Digital print also gets rid of the demand to wash plates or coverings with hazardous chemicals at the end of the printing process.

Variable data assists companies reach their precise customers and audience with uniquely-created and individualized material. As innovation boosts, the quality of digital printing has come to be second-to-none, with greater information, shade suit capabilities and general accuracy. Without the demand to wash plates or use excess ink, digital printing is likewise much less inefficient and generally much more eco-friendly.

Conventional printing approaches, such as balanced out lithography ("offset") and flexography ("flexo"), entail numerous make-ready steps to move an original picture to a substratum. These approaches need the production of a collection of plates mounted on a cylinder to move ink that forms the desired image when incorporated on paperboard and other packaging products. Point of sale stands.

The 10-Second Trick For 24??media

Digital printing, with fewer moving my explanation pieces, is extra agile than offset in this regard.

Lowered set-up time conserves cash on the front end. And considering that these are not enormous mass orders, smaller businesses can pay for to print without having to meet the higher and more costly print limits of conventional printing.

Be sure you team up with a printing and packaging partner that has the right qualifications. While eleventh-hour printing and customization are a significant benefit, electronic may not constantly be the most effective approach for you. Offset printing has the advantage of cost-effectiveness with big print runs, especially those with advanced attractive impacts and specialized coverings.

Our 24??media Ideas

The positive plate, with its smooth surface, attracts oil-based inks and pushes back water. In contrast, the unfavorable plate, with its harsh structure, absorbs water and pushes back oil. Rubber rollers are after that used to transfer the image from the plate to the corrugated surface area.

Corrugated paper can occasionally prove to be a difficult surface area to publish on, but Litho prints to a separate surface and is after that laminated flooring to it, making it easy to print top notch pictures. It can be very constant, also for long runs. In reality, the extra you publish, the less costly the prices end up being for Litho.

What Litho doesn't offer you is specifically what Digital does, personalization. Costly set up Longer turn-around No Variable Information Printing Smaller sized color gamut, shades can be much less brilliant Digital printing is the procedure of printing electronic images directly onto the corrugated substratum utilizing a single-pass, direct-to-corrugate method.

Report this page